Building Materials

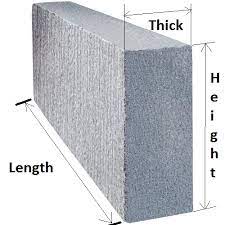

Autoclaved aerated concrete is an innovative building material. It has unique properties that make it better than traditional bricks while giving protection to a building structure in many ways. Moreover, it is environment-friendly and saves overall construction